Oxygen plant process works by taking ambient air from the atmosphere which then separates oxygen from other gases and impurities through molecular sieves and air separation techniques such as cryogenic distillation, PSA (pressure swing adsorption) and membrane separation. We use cryogenic distillation process for its efficiency and capability to generate O2 with purity up to 99.7%, which is sufficient for industrial and medical applications.

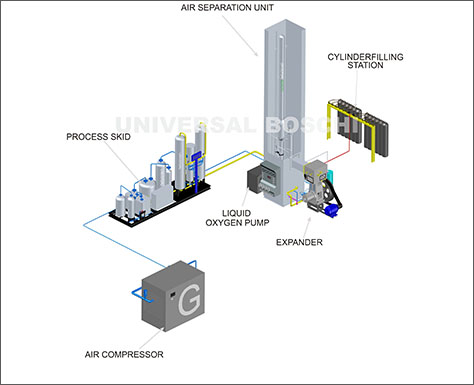

Oxygen generation through cryogenic air separation process starts with intake of atmospheric air through an inlet into the air separation unit (ASU). The air is compressed and purified of impurities such as carbon dioxide, moisture and hydrocarbons. In the cryogenic process, the feed air is liquefied in the series of heat exchangers to sub-zero temperatures. Oxygen is separated from other gases on basis of their boiling points. Finally, the product gas is distilled in the low pressure distillation for achieving commercial purity specifications.

We provide seamless oxygen plant installation at client site. Once all components reach the intended destination, we dispatch our engineer to set up the plant machinery. The engineer will inspect the land and building for commissioning. He also ensures that all the power wiring is connected properly. It is strongly recommended that you keep spare parts for handling future use. Installation materials must be of good quality. Our engineer will take care of everything from erection, commissioning to the starting up of the machinery. Oxygen output is checked out to see if the yield is as per the standard.

|

Technical Specifications |

|||||||||||

| Name of the Models | UBP - 50 | UBP - 100 | UBP - 130 | UBP - 170 | UBP - 200 | UBP - 300 | UBP - 400 | UBP - 500 | UBP - 1000 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacities(Cubicmeter/hr) | 50 | 100 | 500 | 700 | 200 | 300 | 400 | 500 | 1000 | ||

| No. of Cylinders in a Day (Oxygen/Nitrogen) | 200 | 400 | 500 | 700 | 800 | 1200 | 1600 | 2000 | 4000 | ||